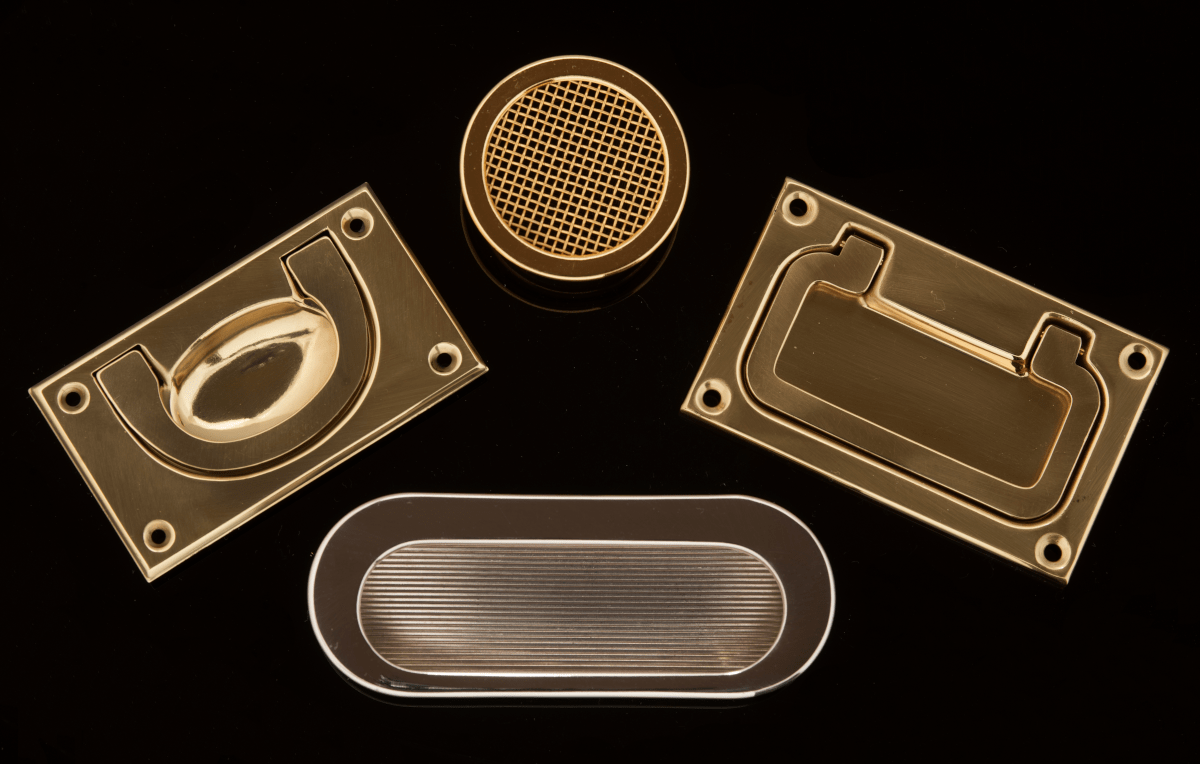

Manufacture of brassware and small metal parts

– Treatments

– Our products can be subjected to different finishes to improve the esthetic appearance, and / or to galvanic treatments, to give them a better external finish and greater resistance to external / chemical agents, and / or to obtain a different color, on request. customer specification.

– The external finishes are distinguished in:

– Antiqued: The antiquing process gives the brass a dated and worn look, while preserving its

consistency and structure

– Nickel plating: And nickel plating through a homogeneous connection with the brass structure allows a durable ennobling of the material and a nickel coloring.

– Satin: Satin is used to refine products and achieve a special high quality matte effect.

– Polishing: Polishing is a surface treatment that makes the appearance of the metal more elegant, giving it shine.

– Bronzing: Bronzing is a process by which the metal is given a color similar to that of bronze, through electrodeposition, giving the product the typical appearance of ancient bronzes.

– Burnishing: Burnishing is a particular chemical treatment, by immersion, which allows to obtain non-stick surfaces, resistant to chemical agents. It also allows to obtain a darker color to metals ensuring high resistance to corrosion.

– Laser cutting: Modern technique that allows metal processing with computerized machines that ensure maximum precision to the thousandth.

– Galvanic treatments, on the other hand, are divided into two large families:

– Containing nickel

– Nickel free

-To ensure maximum resistance of metal surfaces to the most diverse and aggressive environmental conditions, in terms of heat, humidity, salinity and air pollution, we are able to carry out various galvanic treatments and treatments with certified thickness precious metals, both on a nickel and on a hypoallergenic basis.

-We can also provide, upon customer request, laboratory analyzes carried out at accredited centers that measure the quality of galvanic coatings.

-In particular we can perform the following analyzes: • Salt mist • Sulfur dioxide • Moist heat • Thioacetamide • Synthetic sweat • Test (China) • Thickness measurement with XRF

–Epoxy painting: Epoxy paint is a chemical mixture with epoxy resin which, when applied to the surface to be painted, forms a very thin but very resistant external film, capable of preserving the object from the action of external chemical and physical agents.

Thanks to the typical resistance of the thin film, called painting, once applied to the surface, also improves the product from an aesthetic point of view, giving it greater smoothness.

On request it is possible to use a semi-matt varnish, to give the product a less glossy effect.

– Nickel plating: And nickel plating through a homogeneous connection with the brass structure allows a durable ennobling of the material and a nickel coloring.

– Satin: Satin is used to refine products and achieve a special high quality matte effect.

– Polishing: Polishing is a surface treatment that makes the appearance of the metal more elegant, giving it shine.

– Nickel plating: And nickel plating through a homogeneous connection with the brass structure allows a durable ennobling of the material and a nickel coloring.

– Antiqued: The antiquing process gives the brass a dated and worn look, while preserving its consistency and structure.